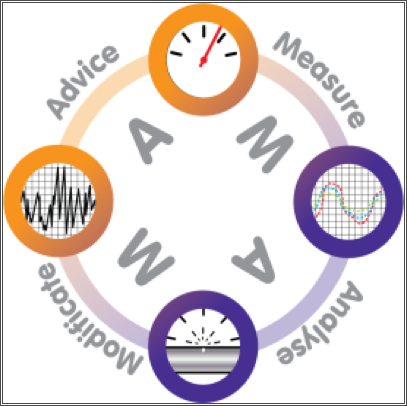

The AQMS® method follows the MAMA circle

Compressed air management is an integral part of energy management. Monitoring will lead to a better understanding of energy waste as result of leakages, compressed air quality and provides valuable information about compressor performance, etc.

Analysis

Analyzing the collected data allows a tailor made solution, e.g.:

How to make the leakages visible as detailed as possible?

How and when repairs can be done to reduce the energy wastage to a minimum without disturbing the production process?

How long will it take to get the system leak tight?

Which materials and instruments are necessary?

What further action is required/justified to optimize the system?

What is the expected payback?

Modifications

Repairing the leakages as soon as possible to avoid remote energy wastage.

Have all the repairs and improvements been completed? What is the result in terms of savings?

When is a new action required/needed? What other improvements can be made?

The optimized system will be monitored on a permanent base

Once the MAMA concept is implemented you’ll start saving money, every day, for many years to come.